An intelligent spend management procurement tool

We’ve combined progressive technology with AI-powered insights and deep expertise in an automated sourcing platform that recommends and engages pre-vetted suppliers for you, making competitive sourcing quick and easy for even the smallest requirement.

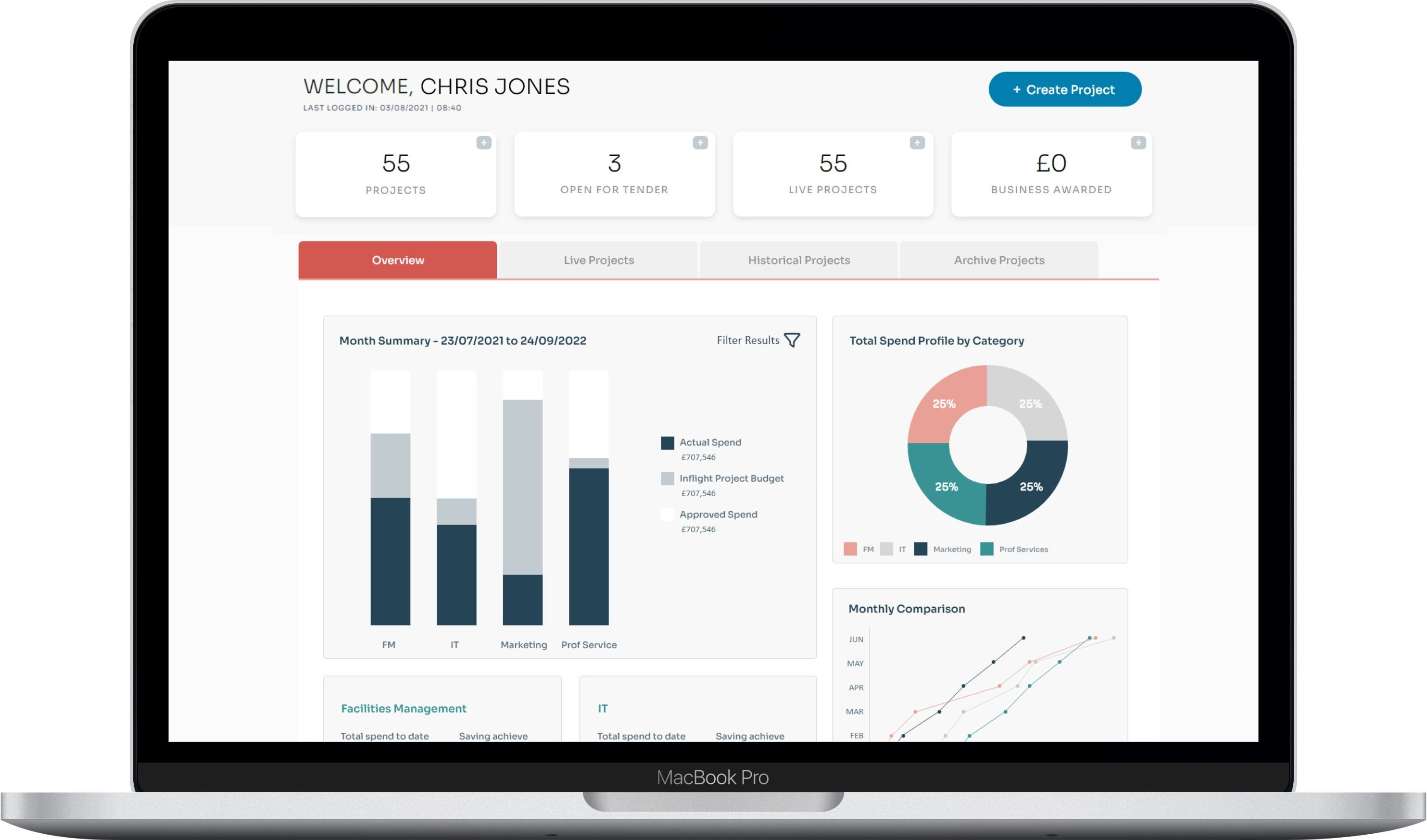

Autonomy with control:Empower and improve local sourcing decisions while ensuring centralised visibility and control for CFOs and CPOs

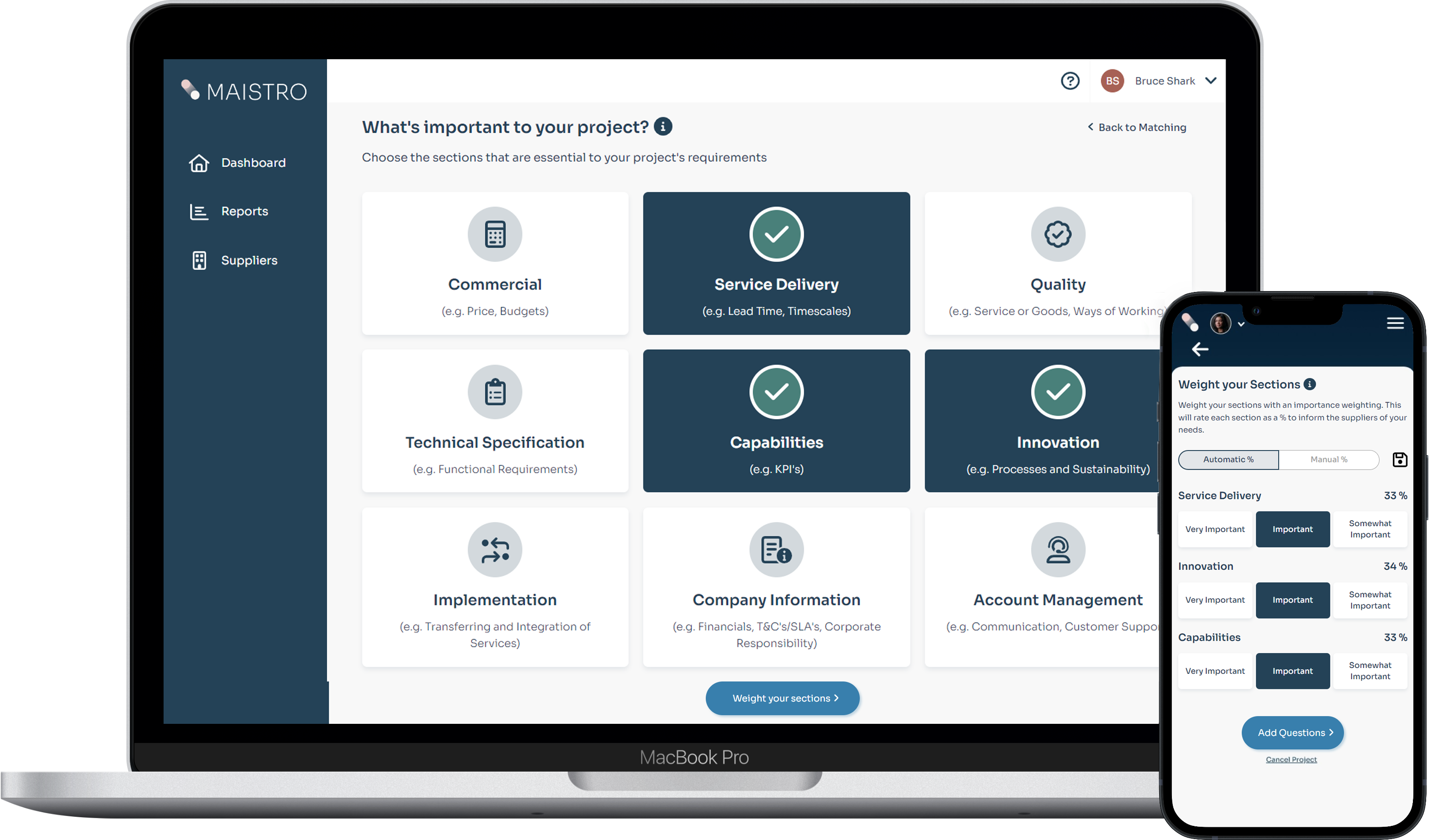

project builder

Smart specification forms automatically translate buyer needs into a Statement of Requirements.

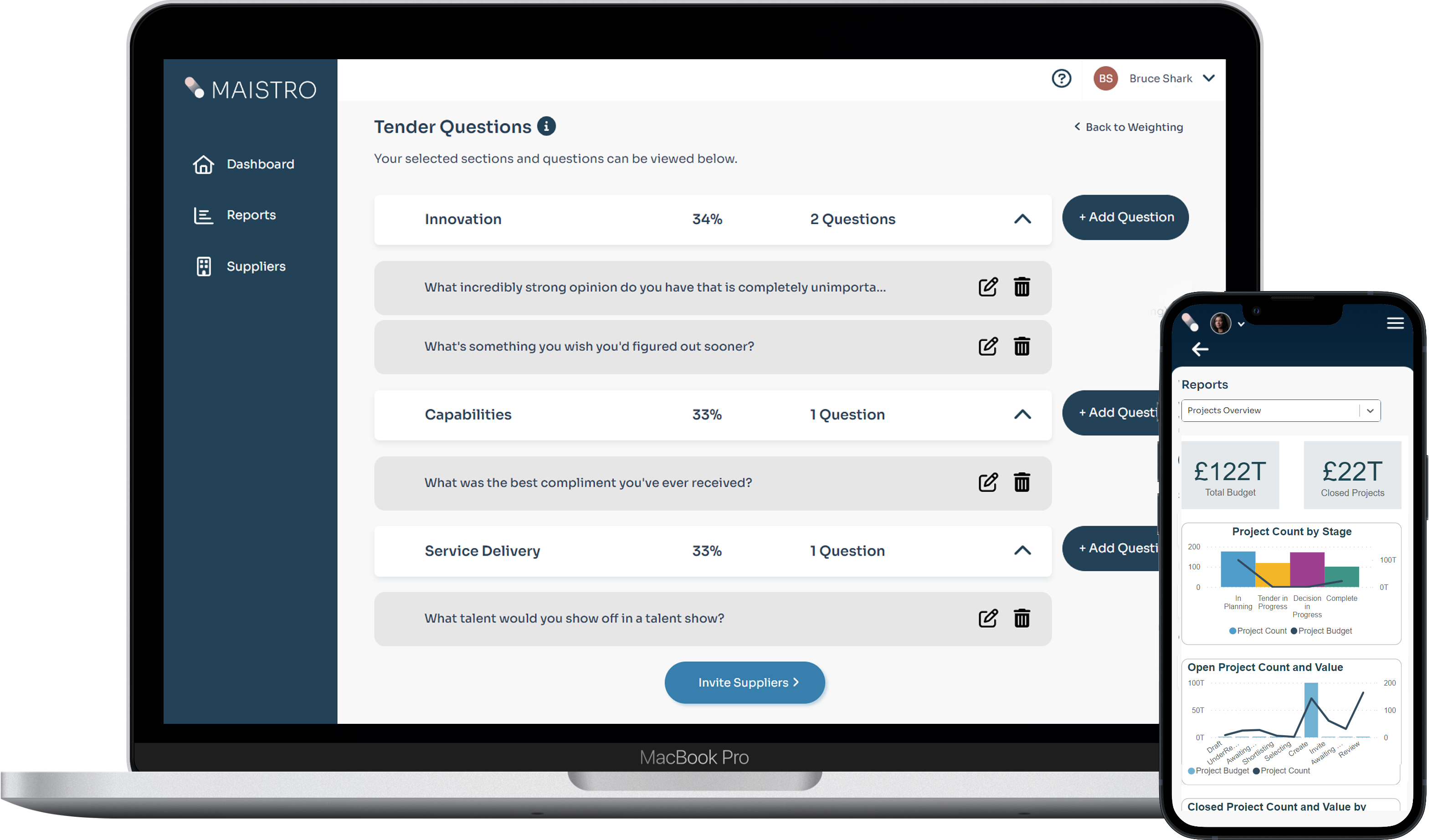

response builder

Quote and tender responses automatically convert into detailed, easy to score submissions.

contract builder

Requirements, responses and prices seamlessly convert to a Statement of Work, replicating your Ts & Cs.

skills builder

Supplier skills & capabilities are automatically converted into a structured profile to maximise potential for matching.

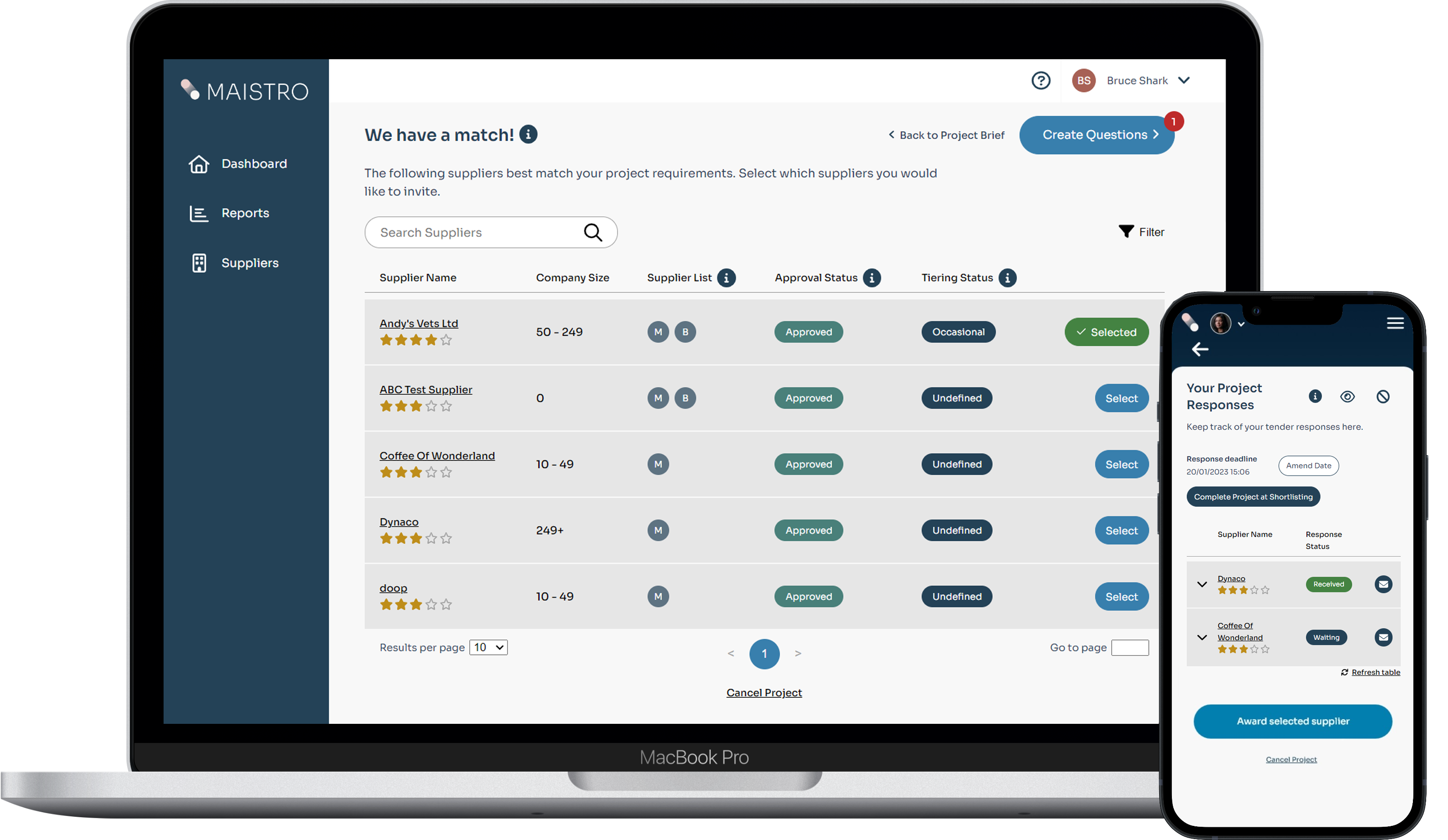

shortlist builder

Evaluation Model automatically assesses bid submissions in terms of quality, cost and compliance.

insight builder

Dashboards automatically monitor progress while data enable faster, better decisions.

We are at your service. How can we help you?

reducecost

By creating an automated online process where buyers can find invite-only suppliers who have provided their credentials, we make sourcing faster and easier

reducerisk

Our platform collects the data that buyers need from suppliers to make fully-informed decisions, helping them identify and eliminate risk

Increase compliance

Risk doesn't end with vetting. By enabling a way to bring more spend under management, we improve data quality and reporting as well as SLA and compliance enforcement

Find responsible suppliers

We enable buyers to spend more responsibly by matching diverse suppliers that present more sustainable outcomes for their organisation